Manufacturing simulation: Optimizing pharmaceutical plant design for smart production

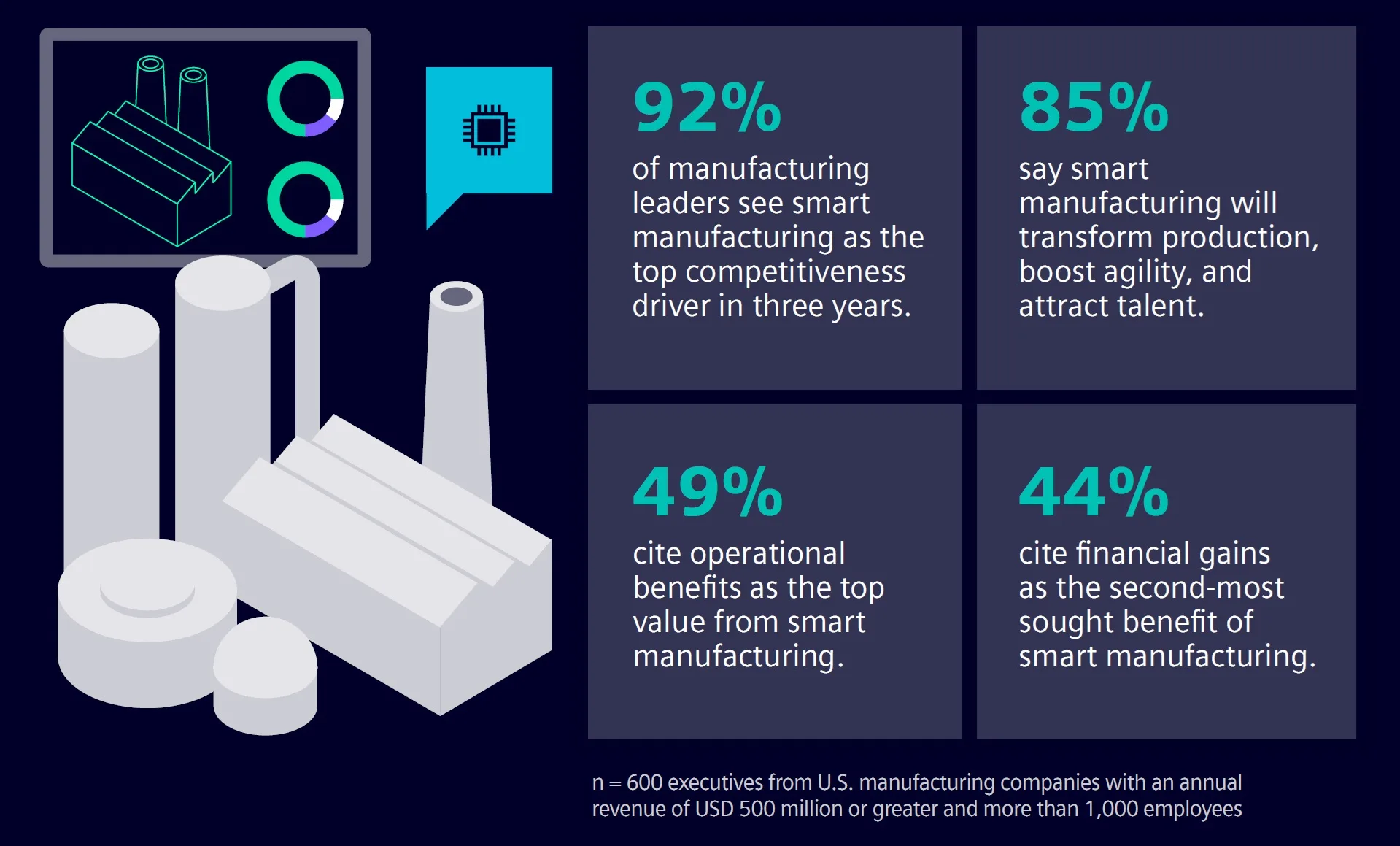

92% of manufacturing leaders say smart manufacturing will be the top competitiveness driver within the next three years. This shift is transforming industries worldwide – and pharmaceuticals are no exception. As the demand for faster innovation, personalized medicine and operational agility grows, pharmaceutical manufacturers must rethink how they design, validate and operate their plants.

The current challenge in pharma production

Pharma production sits at a turning point. Companies need to accelerate time-to-market while managing strict regulations and ensuring uncompromised quality. Traditional, paper-based, siloed processes can no longer keep up. To thrive, manufacturers must move toward digitally connected, simulation-driven environments that enable data-backed decisions across every phase of the production lifecycle.

Rethinking the pharmaceutical manufacturing model with simulation technology

Simulation is transforming how pharmaceutical plants are conceived and optimized. With Siemens Plant Simulation and Process Simulate, manufacturers can model entire facilities virtually, test new designs and fine-tune workflows long before physical construction begins.

This approach replaces assumptions with evidence. By simulating production lines, material flows and process variations, companies can:

- Pinpoint bottlenecks before they occur

- Reduce ramp-up times significantly

- Achieve right-first-time manufacturing

- Increase throughput while lowering costs

- Improve resource utilization

- Maintain compliance and quality standards

Digital twin technology: From digital models to smart pharmaceutical factories

The next step in this evolution is the digital twin – a dynamic, data-driven replica of the plant that reflects real-world performance in real time. By integrating IoT data into simulation models, manufacturers gain continuous visibility into operations and can predict how changes will impact performance before they occur.

A digital twin enables early manufacturability validation, streamlines regulatory alignment and prevents costly late-stage redesigns. With the digital twin market in pharmaceutical manufacturing projected to grow at a 30% CAGR through 2032, the value of this approach is clear: smarter, safer and more sustainable production from day one.

Heading towards autonomous pharmaceutical manufacturing

The future of pharmaceutical production is digital, predictive and increasingly autonomous. As artificial intelligence, robotics, and simulation technologies converge, plants are evolving into self-optimizing systems – capable of:

- Adapting to change in real time

- Minimizing downtime

- Continuously improving performance

Simulation sits at the heart of this transformation. It connects planning with execution, design with operation, and innovation with efficiency.

Simulation: The engine of pharmaceutical manufacturing transformation

For pharmaceutical manufacturers ready to embrace digitalization, simulation isn’t just a tool – it’s the engine of transformation that powers operational excellence, regulatory compliance, and competitive advantage.

Download our infographic to explore the full story of how simulation technology transforms pharmaceutical production. To further discover how digital tools can boost efficiency, throughput and resource utilization, take a look at our white paper “Using manufacturing simulation to optimize pharma plant design”.